Advantages of Aluminium Forging versus Casting to obtain Urban Mobility Vehicles parts

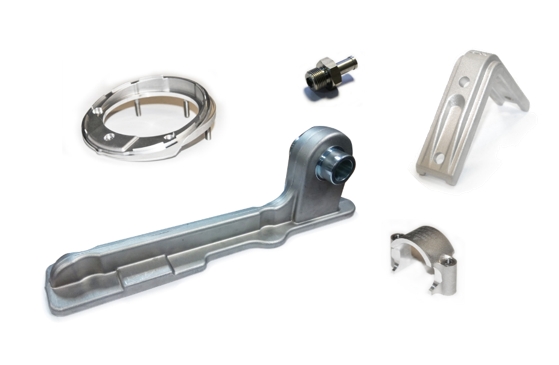

These are some of the advantages of Aluminium Forging process, developed in Aleaciones Estampadas S.A. – AESA for the manufacture of aluminium parts for Urban Mobility Vehicles, Automotive, Railway and other industrial sectors, versus Aluminium Casting parts:

- Superior mechanical properties, improved with Heat Treatment (2000, 6000 and 7000 series)

- High fatigue strength. Preservation of mechanical properties over long time in very demanding conditions.

- High corrosion resistance alloys (5000 series)

- Several surface finishings only reachable through forging process: Anodizing, Chrome plating, Polishing, Shot-blasting, Tribological coatings, Ceramic coatings, etc.

In the following link to our video, you can see the advantages of forged parts compared to parts obtained by casting:

Video presentation Forging v Castings

In AESA we are at your disposal to manufacture your products, by forging and machining lightweight alloys (aluminium, magnesium, titanium, etc.) for Urban Mobility Vechicles parts, as Bicycles, Skateboard, Electric Scooter, Electric Cars, Motorcycles, etc.

For more information: